Additive manufacturing of metallic components involve a large variety of different processes that often leave more questions than usable options. Which of these processes is suitable for my task? Is it only a marginal phenomenon in the rapidly advancing field of additive manufacturing? What is the level of technological maturity for industrial use?

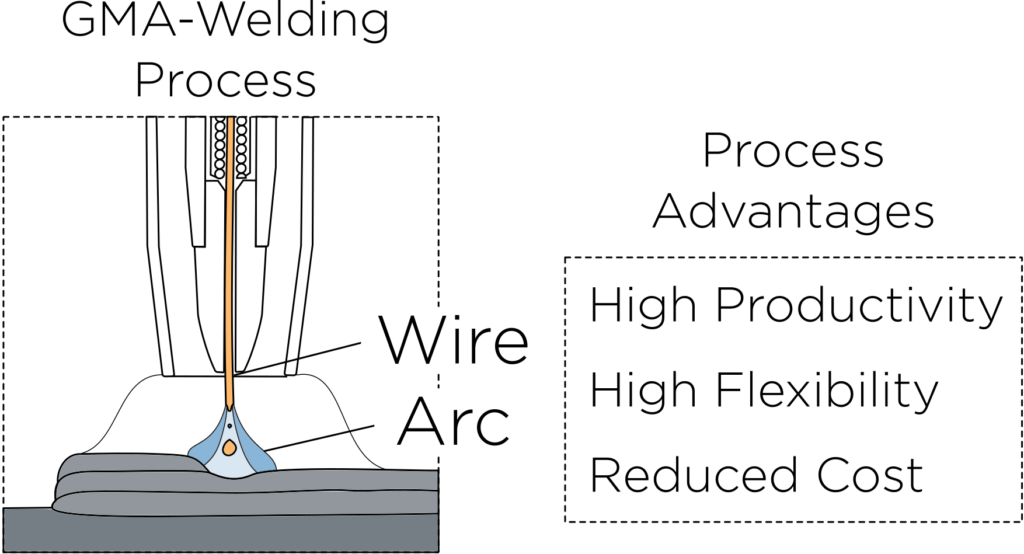

Arc welding, which is a good hundred years old, has produced a wide and affordable range of wire materials and is characterized by maximum productivity and flexibility. So why isn’t everyone already using this technology? The highly productive arc process requires targeted monitoring and control, which are at the core of our unique process technology.

Our Technology

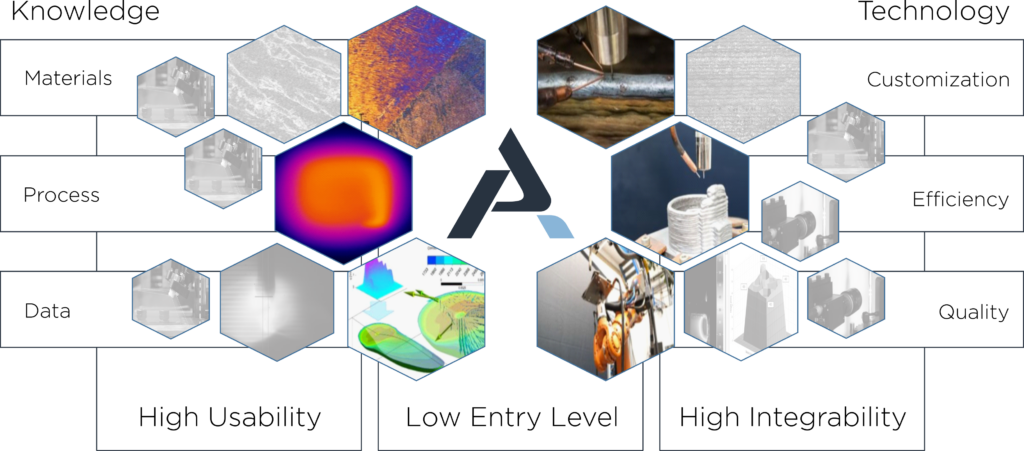

Groundbreaking Innovation, outstanding know-how and unlimited possibilities are inflationary used buzzwords, that make even current currencies blush. What are our convincing arguments? And most importantly, what is your gain for your specific application?

At Plasma Additive, years of engineering experience from welding technology meet novel and thoroughly digitalized automation approaches and process chains. According to our approach, quality monitoring and control are not an add-on, but an inherent element. Multi-material applications not a distant concept, but proven reality.

One of the best arguments for good technology is when it simply works without being to the fore. For this reason we put emphasis on high usability, which allows even untrained rookies to access WAAM. We have a PhD in this field, so you don’t have to. Furthermore, our digitilization approach allows seamless integration into your production systems – as far as it is desired. And last but not least, our systems approach enables a low entry threshold. We have mastered the use of industrial robots, which allow great degrees of freedom. For specific applications, however, we also use portal systems that allow an uncomplicated entry.